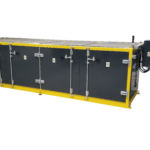

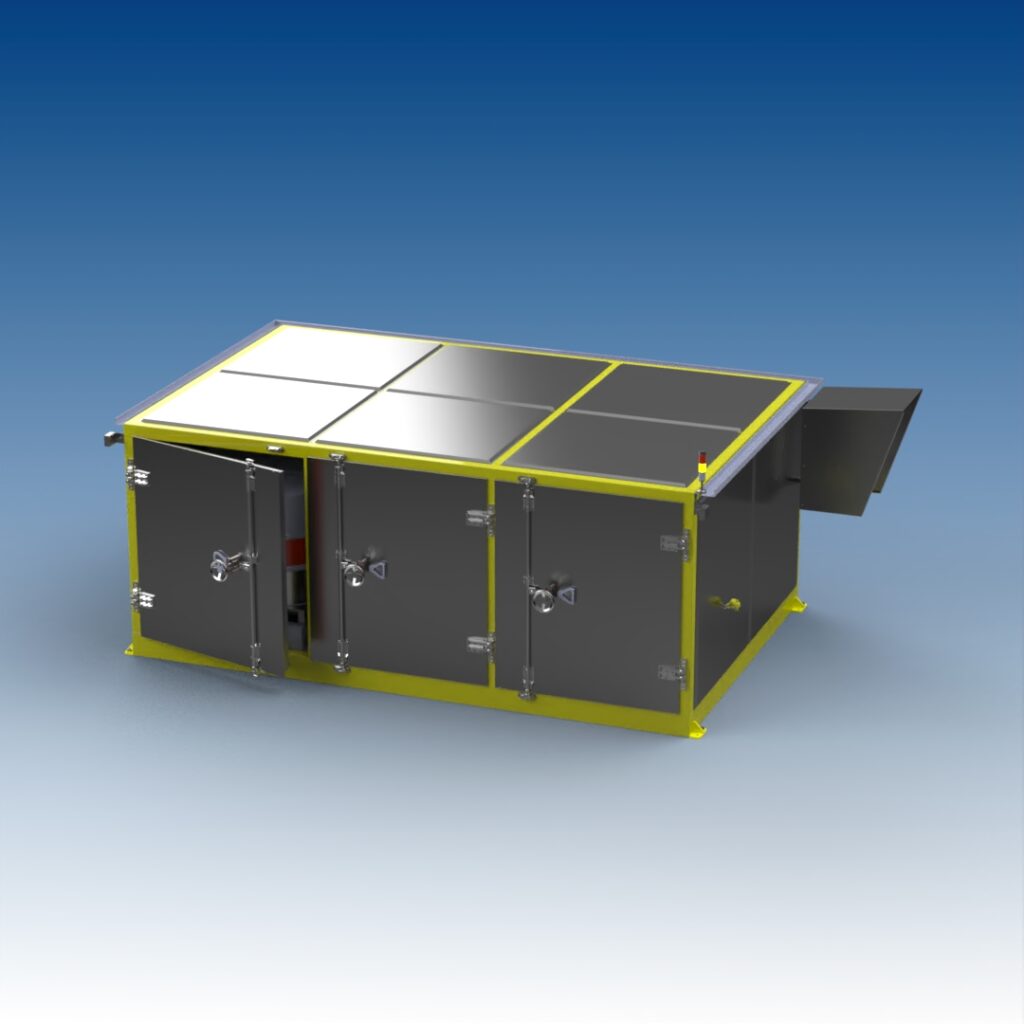

Heating and drying processes of chemical products, finished and semi-finished products are carried out in industrial drying ovens specifically designed for these processes. High precision ovens used for dehumidifying, curing and drying in the materials are used frequently in the chemical industry as well as in the food industry.

Technical Specification

| Material-Cabinet Outside Surface (Not In Contact With The Product) | Elektrostatic Oven Painted |

| Material-Cabinet Inside Surface (In Contact With The Product) | AISI 304 Quality Stainless Steel* |

| Cabinet Exact Dimension For One Pallet | 1400 x 1325 x 1420 mm* |

| Control | PLC & 7″ Touch Screen |

| Total Capacity | 3-12 Pallet |

Advantages

Working Prenciple

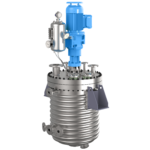

- The saturated steam is pulvarized from the distribution collector into the furnace.

- Based on the indoor temperature, the SAMSON brand proportional valve at the steam inlet performs proportional on-off operation.

Security System

- It works at the highest safety level in its class since it does not contain any mechanical and electrification products with the risk of sparking.

- Stable internal temperature provided by saturated steam

- 100 mm rockwool insulation with A1 class fireproof certificate

- Exproof termocouple

Electrical Automation System

- Control: PLC & 7″ touch screen

- Precise temperature control with thermocouples

- Reliable and sustainable automation system with SIEMENS brand PLC products

- Remote monitoring and integration into existing Scada system

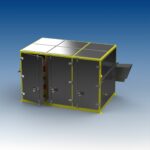

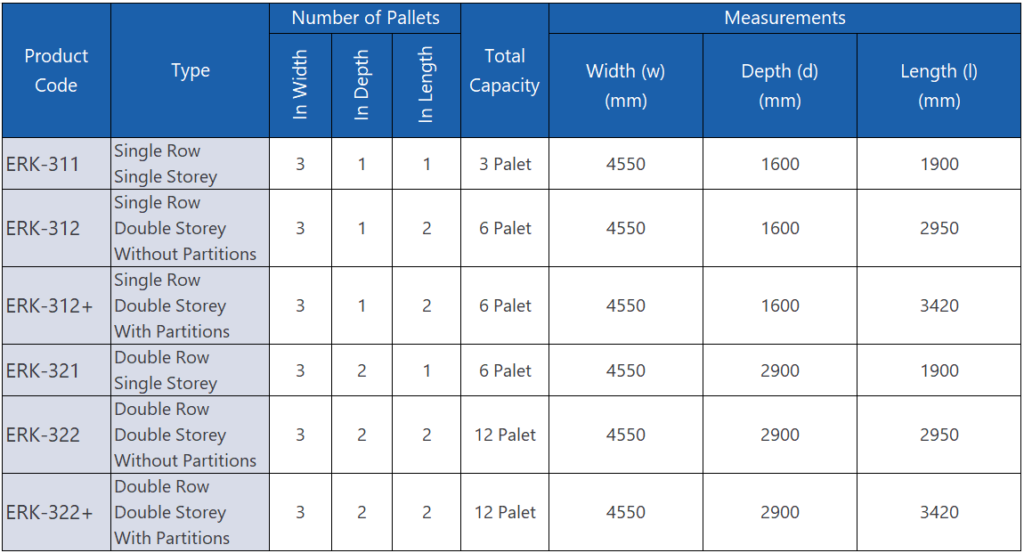

Technical Dimension Table of ERK-300 Series Melting Cabinets

ERK-300 Series includes 6 different products offering customized solutions for your processes. Contact us for more information and to choose the one that suits you best. Our team of experts will be happy to help you to find a customized solution for your needs.

Other Industrial Solutions For Your Process

GEO MELTING CABINET GEO-ERK-300 SERIES are commonly used in below processes.

You can select your own process below in order to check out other related GEO solutions: