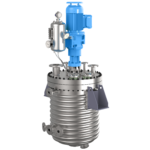

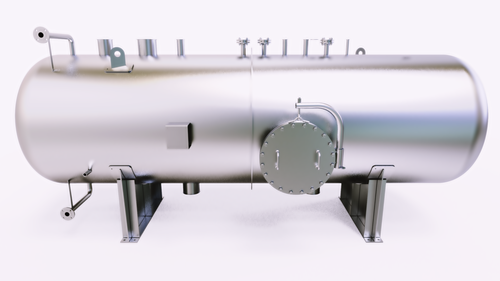

High Performance at High Pressure and Vacuum

Retention of elements such as semi-solids, liquids and gases requires pressure vessels manufactured in high standards. Especially for the chemical industry; pressure vessels usually made of corrosion-resistant stainless steel, must have a design that eliminates the risks of seepage, explosion, wear and loss of protective properties over time.

High Standard Design, Specific For Your Process

GEO carries out the production, installation, service and maintenance of pressurized tanks in accordance with the requirements of each process, product type, temperature, ambient conditions, pressure, vacuum values.

With options such as welding NDT controls, specific design approaches to suit internationa standards, hydrostatic tests under customer supervision and 3rd party control firm certification, GEO has the experience and expert staff to produce the pressurized vessel you need, at high standards and competitive prices.

Carbon steel and stainless steel pressure vessels are mostly requested and used as:

- Storage vessels

- Steam boilers

- Chemical and exproof containers

- Fractional distillation units

- Pressure reactors

- Extreme critical heating and cooling tanks

- Hydraulic reservoirs

GEO offers design, engineering, supply and manufacture of the pressure vessel you need at high standards and competitive prices with CE marking according to PED (2014/68/EN). We provide in-house NDT controls, hydrostatic testing and also collabrate with third party inspectors for various testing and certification processes.

Other Industrial Solutions For Your Process

GEO Pressure Vessels are commonly used in below processes.

You can select your own process below in order to check out other related GEO solutions: