Pressure tanks, which play an indispensable role in today’s industrial and commercial activities, are critical equipment with a wide range of uses. Thanks to their special designs, they offer the opportunity to protect substances such as liquid or gas in a durable way against high pressure and to use them effectively in various processes. In this article, we will try to explain what pressure tanks are, how they work, in which sectors they are widely used, and the important factors to consider when purchasing pressure tanks.

What are Pressure Tanks

Pressure tanks are closed systems, usually designed to store, transport or process liquids or gases. They are resistant to high pressure and ensure that the pressure of the substance inside is maintained. Pressure tanks are usually produced from stainless steel or composite materials and are designed according to the properties of the substance, pressure requirements and intended use. In this way, they perform various functions in different industries.

What is the Working Principle of the Pressure Tanks

Pressure tanks work by keeping the substance placed inside under a controlled pressure. Essentially, the internal pressure of the tank is higher compared to the external atmospheric pressure. This pressure difference allows the substance inside to move in the desired way. This simple principle forms the basis of pressure tanks. Pressure regulators and safety valves ensure safe and regular operation of the tanks.

Where Are the Pressure Tanks Used

Pressure tanks are widely used and sought after in the chemical industry, oil and gas industry, food and beverage industry, automotive, aerospace industry, and chemical transportation and storage industries.

What Are the Types of Pressure Tanks

Pressure tanks can be divided into various types based on different industrial needs and intended uses. Commonly used pressure tank types are:

- Storage Tanks: These types of tanks are used to store liquids or gases. Storage tanks are often used in fields such as power generation, the chemical industry, and gas distribution. They can be of different capacities and designs depending on the material to be stored and the application.

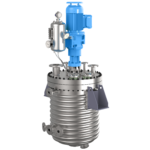

- Pressurized Reactors: These are closed systems in which chemical reactions are carried out. Reactor tanks are used in the chemical industry, pharmaceutical production and various synthesis and conversion processes. These tanks are designed for reactions that can be controlled under specific temperature and pressure conditions.

- Food and Pharmaceutical Industry Tanks: Tanks specially designed for the storage and processing of liquid or semi-solid products in the food and pharmaceutical industries. Hygiene and product safety are at the forefront.

- Air Tanks: Used to store compressed air produced by air compressors. These tanks, which are frequently used in industrial machinery, automation systems and power generation, play a stabilizing role against sudden weather demands.

- Heat Exchangers: Heat exchangers are devices that transfer heat from one environment to another. It is heavily used in sectors such as power plants, Petrochemical, Food and beverage industry and Automotive industry.

- Steam Generators: These tanks are systems that produce steam by heating water. It is used in applications such as energy production and process heating.

The above examples are just a few of the different types of pressure tanks. Each type of pressure tank is specially designed for a particular industry or process and is manufactured in accordance with the properties of the material they contain, as well as the pressure and temperature requirements.

5 Points to Consider When Purchasing a Pressure Tank:

When purchasing a pressure tank, you need to consider some important factors to make the right choice. Here are 5 critical points you should pay attention to when purchasing a pressure tank:

- Material Quality and Durability: Material quality and durability form the basis of a long-lasting and safe use in the selection of pressure tanks. Especially in industrial applications, the material used in the production of the tank is of great importance. To prevent contamination and bacterial growth, you should choose materials with high durability, such as stainless steel.

In addition, the choice of material should be in accordance with the properties of the material you will store in the tank. You can provide long-term performance by choosing materials that are resistant to chemical reactions and corrosion such as stainless steel.

- Size and Capacity: The storage capacity and dimensions of the pressure vessel should be suitable for the requirements of your process. You should choose the capacity of the pressure tank correctly, taking into account the amount you want to store. In addition, the dimensions of the tank should be suitable for the area in which it will be used and should be compatible with the available space in your facility.

- Safety and Certification:: There are certain standards and safety requirements for pressure vessels. For example, the 2014/68/EU standard, which is the European Union Pressure Equipment Directive, and the EN 13445 standard, which shows the rules for the design, manufacture and quality control of Fireless Pressure Vessels. Choosing a tank that meets these standards is important to ensure safety in your workplace.

- Pressure and Leakage Tests: The durability and sealing properties of the pressure tank you will purchase must be well documented by the manufacturer or supplier. Pressure tests and tightness checks should be performed to confirm compliance with the relevant standards. This is a critical step to ensure safe use of the tank.

- Technical Support and Consultancy: Getting technical support and consultancy while purchasing a pressure tank will enable you to make the right decision. Working with a team of experts in the field, you can choose the tank that best suits your business needs. Technical experts can offer customized solutions based on your intended use and process requirements.

Choosing the Right Pressure Tank For Your Business

These tanks, which have wide application areas in different industries, can increase efficiency and ensure operational safety with the right choices. When purchasing a pressure tank, you should carefully consider your process requirements, paying attention to material quality, design features and safety standards.

As GEO Tekno, with over 25 years of experience, we can help you select the pressure tanks you need and provide you with the most suitable solutions through our experienced design and manufacturing departments. If you need a pressure tank for your process, all you have to do is to contact us.

Do not hesitate to contact us for your questions. Choose our certified pressure tanks to maximize your process performance!

For further information,

Check our product page for GEO pressure tanks

+90 232 459 49 09