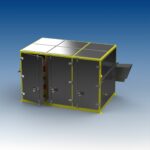

What is GEO Cyclone Separator?

Cyclone separating tanks’ unique design allows a centrifugal air flow in them, allowing the particles to separate from the air with the effect of this spinning motion. Cyclone prices are more affordable than industrial filters. Stainless cyclones are generally used as a protection layer before or after industrial filters and equipment, as they can separate certain sizes of particles.

Usage Areas of GEO Cyclone Separator

The contaminated air, which enters the cyclone, rotates inside the steel cyclone body, pushes the particles to the edges and separates them. Thanks to the centrifuge separation, these particles lose their inertia, fall under the tank and exit. The air rises again and finds its way.

A few examples of the usage areas of cyclone separators:

- Abrasives

- Packaging Machinery

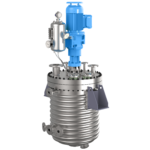

- Food processing and hygienic facilities

- Chemical, pharmaceutical and cosmetic processes containing powder

- Grinding, Screening and Separation Processes

- Boiler Applications Using Solid Fuel

- Wood Industry

- Paper Industry,

- PVC Stabilizer and other process powders,

GEO Cyclone Separator Price

GEO cyclones, which can be manufactured in a wide range of 2 to 150 micrometers, made of stainless steel or carbon steel, are designed according to many parameters from particle size to tackiness, abrasiveness to inlet air temperature and centrifugal pressure drop value. You can contact our team for GEO cyclone prices, which are economical and low-priced despite the high quality.

Other Industrial Solutions For Your Process

GEO Cyclone Separator Tanks are commonly used in below processes.

You can select your own process below in order to check out other related GEO solutions: