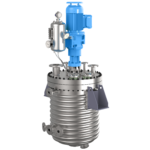

Highly Efficient, Long Lasting

GEO, with its expert staff and strong database, helps its customers to choose the most suitable mixer solution to use in their processes with detailed analysis. For renewal of existing mixer tanks or potential purchasings of new mixer tanks, do not order tanks without getting a quotation from us.

Suitable for Every Need

Whether 500 liters or 50 tons, from the smallest capacities to the highest mixing speeds, mobile, fixed, vertical, horizontal, industrial, hygienic, stainless or carbon steel, GEO’s tailor-made, special design mixers are ideal for all kinds of mixing operations.

Conical Bottom: Ideally, the cone angle is expected to be less than 15 ° for homogeneous flow. Any angle less than 30 ° can also be accepted in cases where product will be emptied from under the mixer. If a cone is too deep, it becomes much more difficult to provide a good mixture in it.

Dished Head Bottom: Usually a cambered base is better for solid suspension since there are no sharp angles in the tank, so it eliminates dead spots. But the same can be achieved with a rounded conical base. Curved tank bottoms are more suitable for pressurized applications.

Compartments: If a cone / round bottom tank is too deep, compartments can also be placed inside the tank to promote good axial mixing and prevent eddy formation.

GEO Quality

Most of the parameters that determine the homogeneous mixing speed are directly related to the mixer tank design. Many details such as blade types, mixer shaft length, tank diameter ratio to the level of mixing solutions becomes the best quality solution suitable for your budget, with the help of GEO’s many years of expertise on industrial mixer manufacturing.

Other Industrial Solutions For Your Process

GEO Industrial Mixers are commonly used in below processes.

You can select your own process below in order to check out other related GEO solutions: