In a competitive marketplace with rapidly growing beverage consumption, beverage production companies need the right partner designing and building a safe and high-quality beverage production plant. In this regard, there are several significant points to consider:

1.Putting Beverage Hygiene and Safety First

Beverage hygiene and safety begins with the overall plant design due to the sensitive nature of beverage processing. Designs leading to deficient beverage safety and hygiene entail detrimental risks to public health and environmental safety. Here, the ideal design for your beverage processing equipment should be prepared considering prevention of any contamination due to toxic contaminants. It should also eliminate any contamination resulting from the microorganisms causing illnesses. Therefore, it is of great significance that you choose the right solution partner that provides you with safe and aseptic beverage production/processing equipment.

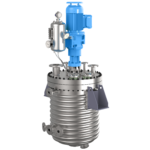

The right steel:

The operating conditions play a vital role in selecting the right grade of steel. For instance, temperature and acidity have an effect on the selected material. In general, the stainless steel roughness factor should be between 0.3 to 0.8 μm since hygiene is a significant concern for a beverage production plant.

The right welding process:

Continuous, round, ground, polished and smooth welds are essential to manufacture hygienic stainless steel equipment. A smooth welding procedure will prevent creating crevices that can result in contamination due to bacterial growth. Furthermore, a void created by welding a lap join entails risks of harboring bacteria. Therefore, the continuity of the welding procedure is of great importance.

Pickling and passivation:

The stainless steel equipment you need for your beverage production plant should be properly cleaned. Thus, it is necessary that the stainless steel does not suffer from corrosion and pitting. A fully pickled and passivated stainless steel surface will prevent the corrosion and pitting risks.

2. Personal Safety

A safe environment for your personal can be provided by selecting the right beverage processing equipment for your company.

3. Sustainability

An ideal beverage production plant optimizes its daily operations by reducing its carbon footprint via sustainable resource management and water reduction. A sustainable resource management will lead to the best solutions for energy, water and other utilities and reduce product waste. Here, the 17 Sustainable Development Goals of United Nations provide guidelines for a sustainable beverage production plant.

4. Capacity

In general, it is important that your plant produces the desired amount of beverage in the desired duration considering changing waste amount and plant downtimes. An ideal beverage production plant design needs to have a scalable capacity in order to adapt to changes in the market demands resulting from new technologies and trends. The scalability will eliminate the need for a full re-design process.

GEO has the necessary technical expertise and know-how to tailor-fit services and solutions for your company. Our concept aims to provide a total process solution for beverage companies/ production facilities. Our solution focuses on:

- Increasing your production rates

- Helping you achieve food safety compliance by conforming to ISO and EN guidelines and regulations

- Reducing CAPEX and OPEX

- Optimizing energy efficiency by minimizing carbon footprint

We can help you design and build a safe and high-quality beverage facility to accelerate your growth and ensure your success.