Buying a stainless steel tank has become widespread with the recognition of the characteristics of stainless steel by potential buyers. You can see small or huge stainless steel structures, usually consisting of superimposed horizontal cylinders, all over the world.

So how these structures with such a simple appearance have become so widely used in countless sectors such as food, agriculture, chemistry, construction and packaging?

The answer is hidden in stainless steel tank prices. The long-lasting structure of the stainless steel tanks, the fact that they do not lose value for decades and do not compromise on their characteristics, provide buyers great advantages in terms of cost. Whether you are a food manufacturer or a chemical manufacturer, stainless steel tanks will improve your business. So what to consider before buying a stainless steel tank?

1 – Technical Drawings

It will be for your benefit to ask for the technical drawings including the perspective view with the offer for stainless steel tank. Many aspects such as alignment of the flanges, overall dimensions and capacity of the tank, position and opening direction of the lid can create major problems when design is incompatible with your plant and the stainless steel tank. If the tank you buy is a stainless steel process tank, its place in the process may not tolerate such errors.

There are a lot of things to consider before buying a stainless steel tank. The easiest way to ensure the suitability of the tank for your business and process is by requesting technical drawings or negotiating with a tank manufacturer experienced on building turnkey factories. The small changes you make on the technical drawing will make the tank specific for your process.

2 – Stainless Steel Tank Welding Method

The first thing you ask to the manufacturer for tank orders should be manufacturing techniques, not the stainless steel tank price. One of important factors that affect the life of your new tank is the welding technique which most people ignore. Asking to the manufacturer about the welding methods to be used in your tank will prevent you from having negative experiences in the future.

3 – Surface Characteristics of Your Tank

Any mechanical treatment during the manufacturing process causes the oxide layer in stainless steel to deteriorate. Request pickling and passivation from your manufacturer after welding your stainless steel tank. In order to prevent scratching of the outer surface during the manufacturing, transportation and assembly stages, sheets should be PVC coated. If it is a food tank, be sure to warn your manufacturer that the internal welding seams should be polishing to prevent bacterial growth on the inner surface.

4 – Hydrostatic Test

When you ask your manufacturer whether they have tested for working pressure, their answer will be probably “yes“. However, an accurate hydrostatic test must be performed at values above the working pressure and for each tank you have ordered. Regardless the price of stainless steel tank, products that have not been tested hydrostatically should not be purchased. Always ask for the hydrostatic test report containing the manometer photographs taken at the time of the test.

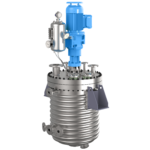

Buying a stainless steel storage or process tank can be tricky. This is why, We continously update our blog with useful information on the topic. GEO Tekno designs, manufactures, tests, installs and maintains stainless steel integrated process solutions. Our Integrated solutions includes a lot of different types of products.

Our most requested stainless steel solutions include food or chemical reactors, stainless steel hygienic storage tanks and process tanks. Our team of engineers also design and realize tank farms, production facilities and plants of special processes for more than 25 years. You can check out our stainless steel tank solutions from here.