Olive production is a culture with 6000 years of history. Olive oil production starts with olive harvest. In the past, olive harvesting was carried out by hand picking. Today, the harvest is carried out with various machines that allow the olive branches to shake by shaking the tree branches. Spilled olives fall under the tree slopes placed in a single pool.

After harvesting, the olives are washed and filtered through grids to getrid of leaves, branches and dirt. The highest quality olive oils are obtained within 24 hours after harvest.

Olive oil processing can be examined in two ways under the heads of traditional and modern methods:

1 – Traditional Olive Oil Processing Steps

The traditional olive oil process begins with crushing the olives. The aim is to facilitate the separation of the oil from the particels. This crushing process is carried out with large marble stones.

In the next step of the olive oil production process, the olives are mixed for 20-50 minutes. The mixing process ensures that large and small drops of oil are joined together and that the finely ground olives achieve the desired aroma and flavor.

The olive paste obtained after crushing and mixing processes is passed through superimposed fiber discs and then hydraulic press. Pressure up to 4000 kPa forces the product to change from solid to liquid.

The liquid is then separated for precipitation and centrifugation.

2 – Modern Olive Oil Production Steps

Modern olive oil mills are partially or fully automatic and made from stainless steel bodies and grinders instead of marble crushers /crushers. Shredded olives are thrown into stainless steel process equipment called hammer mill. Alternatively, toothed discs, cylinders or roller mills are used. One of the tricks here is that the mill should run slowly to prevent crushing from overheating. During oil processing, the olive oil temperature should never exceed 27 degrees.

Modern zeytin karıştırıcılar(malaksörler) yatay oluklu ve spiral karıştırma bıçaklı çelik makinelerdir. Ezilmiş zeytinleri tipik olarak 10-20rpm hızlarında, 20 dakika ile bir saat arasında karıştırır. Bu işlemde verimin artması için su ilave edilebilir, ancak bu genellikle yağın kalitesinde azalmaya sebep olur.

Modern olive mixers (malaxators) are steel machines with horizontal grooved and spiral mixing blades. It mixes the crushed olives at speeds of 10-20rpm, typically between 20 minutes and one hour. In this process, water may be added to increase the yield, but this generally leads to a decrease in the quality of the oil.

The liquid separated by centrifugation passes through industrial oil shafts and filters that aim for minimum oxygen contact in the next stage. In large enterprises there are machines that produce at least 3 tons of olive oil per hour.

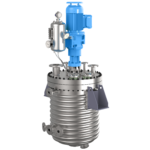

The most important elements of the process are undoubtedly olive oil storage tanks. The wrong choice of olive oil tanks can cause the whole olive oil process to be wasted. If the feature of olive oil to easily absorb the odors in the environment is not prevented, the characteristic of the oil is significantly affected.

The humid air adversely affects the quality, the light above certain lumen adversely affects the shelf life, the excess heat adversely affects both shelf life and taste of the oil. To slow down the oxidation process, food-friendly, high quality stainless steel olive oil storage tank should be purchased. When requesting an olive oil tank offer from a company, there are some points to take into consideration;

If the company gives priority to the food sector,

And if it has a contracting history.

Refined process such as olive oil processing needs experience to manufacture storage tanks at sufficient qualification. So, choosing an experienced,like quarter-century experienced, manufacturing company is for the benefit of you.

3 – Modern Olive Oil Tank Storage Solutions

If you are looking for tank solutions for your olive oil process, you can review our Olive Oil Processing product gallery.