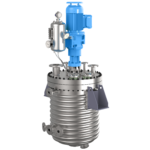

Clean-in-place systems known as CIP systems are becoming increasingly popular, especially in the food and beverage manufacturing industry. The CIP system design allows the inner surfaces of a storage tank and the lines emerging from it to be cleaned more effectively and efficiently without having to get into the tank. They also provide thorough cleaning by preventing exposure to harmful chemicals contained in storage tanks or contamination of food and beverage mixes.

Many tanks used in food and beverage are equipped with stainless steel or metal pipes that need to be cleaned regularly to keep bacteria away, and the stored material will be consumed by humans at the end of all processes. CIP tanks help to meet standards set to ensure a clean and bacteria-free product.

ADVANTAGES OF CIP SYSTEM

- Minimizes Errors: It removes cleaning from the human factor, reducing the possibility of human error that could affect the product in an unsafe way.

- Keeps Employees Safe: As CIP systems contain cleaning solutions, the exposure of the cleaning person to chemicals is reduced.

- More Production Time: Since less time will be spent on cleaning thanks to CIP systems, more time is spent for production.

- Product Quality: Reliable and repeatable cleaning means sustainable product quality and consistency. Less contamination means less product recalls and higher brand reliability.

- Energy Saving: Repeatable cycle control is provided with CIP systems, thus water and energy usage is reduced.

A central CIP system is a single system that provides cleaning solutions to the entire process plant. It can supply many different circuits and coordinate multiple processes from a single location so that operators can manage processes using a central control set.

CHOOSING THE RIGHT CIP SYSTEM

CIP systems vary greatly according to the following features and the sector in which it will be used;

- Configuration

- Capasity

- Quality

- Automation level

Differences in product specifications and legal considerations between various processing industries are among the factors that affect the design of the CIP system preference. Depending on the system and the product being cleaned, the CIP system can be simple enough to clean a small circuit or complex enough to serve multiple circuits simultaneously.

Needs analysis and proper planning leads you to CIP System designs that increase the safety and efficiency of your process. While choosing the right CIP system, it would be helpful to consider followings:

- Your system layout

- Your budget

The location of a central CIP system in a factory is important. A centralized system can be cost effective if all processing areas are relatively close and all have similar cleaning requirements. To ensure that you get the maximum return on your investment in a CIP System, you should first of all hire an experienced engineering firm that understands the process systems, will design and manufacture the CIP System, and be with you from installation to post-delivery services. You can contact us to choose the most suitable system for your process and get support from our experienced engineering team.