Do you wish to turn freshly gathered seasonal fruits into highly sweet dried fruits while retaining their fresh aroma?

So let’s take a closer look at what you should know about infusion plants.

1. Infusion Plant Process Steps

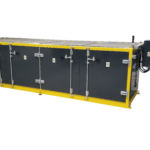

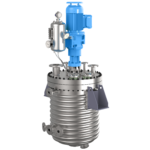

The infusion plant allows freshly picked fruits to be dried by osmotic dehydration by immersing them in a highly concentrated syrup. While the color and flavor of the fruits that are dried by brewing preserves the freshness of the first day, they do not need any preservatives and sweeteners. The process steps of this facility can be summarized as follows;

- Syrup preparation

- Transfer of syrup to infusion tanks (syrup filling)

- Hot circulation, cold circulation

- Returning the syrup to the tanks (syrup discharging)

- The product consists of loading and unloading steps

2. Food Product Usage Areas Processed with the Infusion Facility

Dried fruits with a rich and deep flavor are commonly used in modern cuisine applications. In the food sector, where fast-moving consumer goods are developing and diversifying, customers' preference for organic products is growing by the day. As a result, different investment opportunities in the food business have emerged. The areas of the food sector that can be served as a result of the infusion facility investment include:

- Cakes and Bakery Products

- Snacks for Health

- Dairy Products

- Bread

- Muesli and Cereals

- Chocolate and Confectionery…

3. Which Products Can Be Processed With the Infusion Plant?

Almost all fruits can benefit from the management of fruit drying immersed in high-concentration syrup (osmotic dehydration). Because of the infused drying that you will use in many items, you may extend the consumption life of the fruits in their natural flavor without sweetening or adding sugar. You can infuse drying with the following products:

| Apple | Blackberry | Raspberry |

| Blackcurrant | Blueberry | Strawberry |

| Cherry | Sour Cherry | Plum |

| Cranberry | Elderberry | Apricot |

| Goji | Golden Strawberry | Melon |

| Lingonberry | Pomegranate | Peach |

4. The Benefits of Infused Dried Fruits

GEO Infusion Facility is built and commissioned with user-friendly technology and equipment to make production easier for you. The most significant advantage is that it maximizes your company's efficiency during the production phase. Furthermore, the benefits of brewed dried fruit manufacturing due to the infusion facility are as follows:

- Because high temperature/phase change is not required in the process, it limits the effect of temperature on food quality and protects the food’s integrity.

- Mild heat treatment aids color and flavor preservation, giving the product outstanding organoleptic qualities.

- It protects the product from structural collapse during later drying. It aids in the retention of form in dried items.

- Enhances the characteristics of tissue and rehydration. Continuous immersion in osmotic agents prevents oxidation, allowing the product to retain its color longer.

- Demlenmiş kuru meyveler, sadece meyvenin şekeri ile tatlandırılırlar, ilave tatlandırıcı ve lezzet artırıcı ürünlere gereksinim ortadan kalkar.

- Infused dried fruits are sweetened solely with fruit sugar, avoiding the need for extra sweeteners and taste enhancers.

- No need for additional fees helps you lower your operating expenses due to the naturalness and ease of the process.

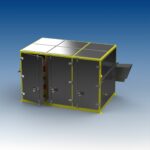

5. Infusion Plant Equipment Integration

Other equipment in your production area that you will want to add to the infusion facility in order to get the most out of your business. GEO has more than 25 years of experience in project design, engineering, plant and process equipment production in the food sector, as well as many other industries. The engineering team analyzes your production expectations and demands in the best way possible, thanks to GEO's facility experience, and provides integrated solutions for you.

GEO R&D creates custom designs and projects for you to achieve the best results for your infusion facility requirements. By developing a fully automated-robotic infusion facility, GEO will help you maximize your profit and market share while minimizing your costs. Furthermore, GEO promises that integrated solutions such as automation and drying oven will add value to your infusion facility.

We focus on our customers' demands, create them, produce them, and put them to use using our unique techniques and experience. We boost your market strength in the food business. For more information;

Take a look at the GEO Turnkey Projects Page Send us an e-mail +90 232 459 49 09

Tagged Infusion Plant